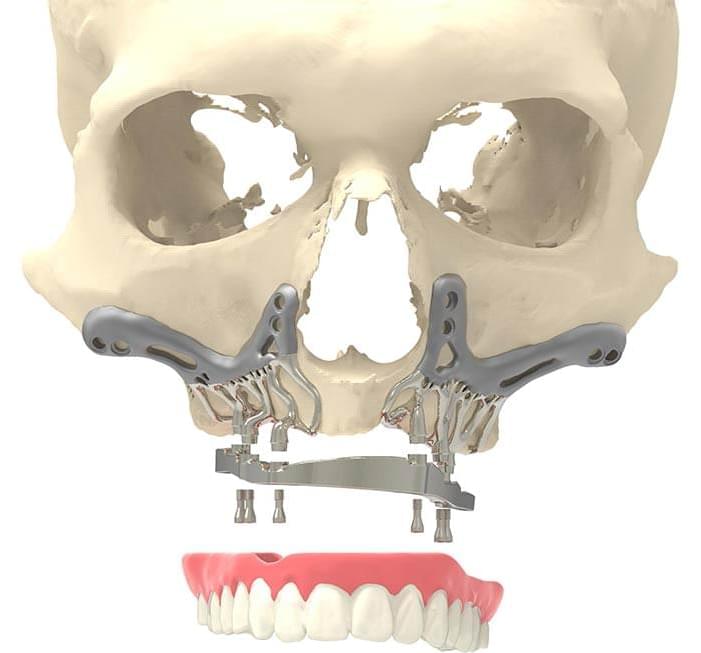

An 83 year-old woman in Belgium had a severely infected jawbone, and researchers and doctors were able to replace it with the world’s first 3D printed jaw.

CADskills is a medical device startup based in Ghent, Belgium. Their expertise lies in patient-specific implants, with a focus on CMF and neurosurgery patients. What is putting them in Materialise’s spotlight however, is their AMSJI: a revolutionary 3D-printed titanium jaw implant that will make life better for extreme maxillary atrophy sufferers. Now there’s something to […]

Join us on this fascinating journey as we delve into the world of 3D printing and bring a brain to life. From designing the complex neural networks to layer by layer printing, we’ll take you through the entire process of creating a realistic brain replica using cutting-edge 3D printing technology. Witness the intricate details and textures that make this brain model a true marvel of modern innovation. Whether you’re a science enthusiast, a 3D printing aficionado, or simply curious about the possibilities of additive manufacturing, this video is sure to leave you amazed and inspired. So, sit back, relax, and get ready to explore the incredible world of 3D printing.

🧠💡 Thinking about organ transplants?

🔬 A team of scientists at the University of Wisconsin–Madison has achieved a groundbreaking milestone!

🌐 They’ve developed the world’s first 3D-printed brain tissue that mirrors human brain function.

🚀 This is a giant leap forward for research into neurological and neurodevelopmental disorders.

🖨️ Utilizing a horizontal layering technique and a softer bio-ink, this 3D-printing method allows neurons to weave together, forming networks similar to those in the human brain.

🔍 This precision in controlling cell types and arrangements opens new doors for studying neurological conditions, including Alzheimer’s and Parkinson’s disease.

#HumanBrain #TechNews #3DPrinter

A team of physicists from the University of Amsterdam’s Institute of Physics has 3D-printed a Christmas tree made entirely of ice. Researchers Menno Demmenie, Stefan Kooij and Daniel Bonn used no freezing technology or refrigeration equipment—just water and a vacuum. In time-lapse videos, you can see how the Christmas tree is printed and how it melts again when the vacuum pump is turned off. The work is published on the arXiv preprint server.

The secret of the tree lies in so-called evaporative cooling. This is the same principle mammals use to regulate their body temperature.

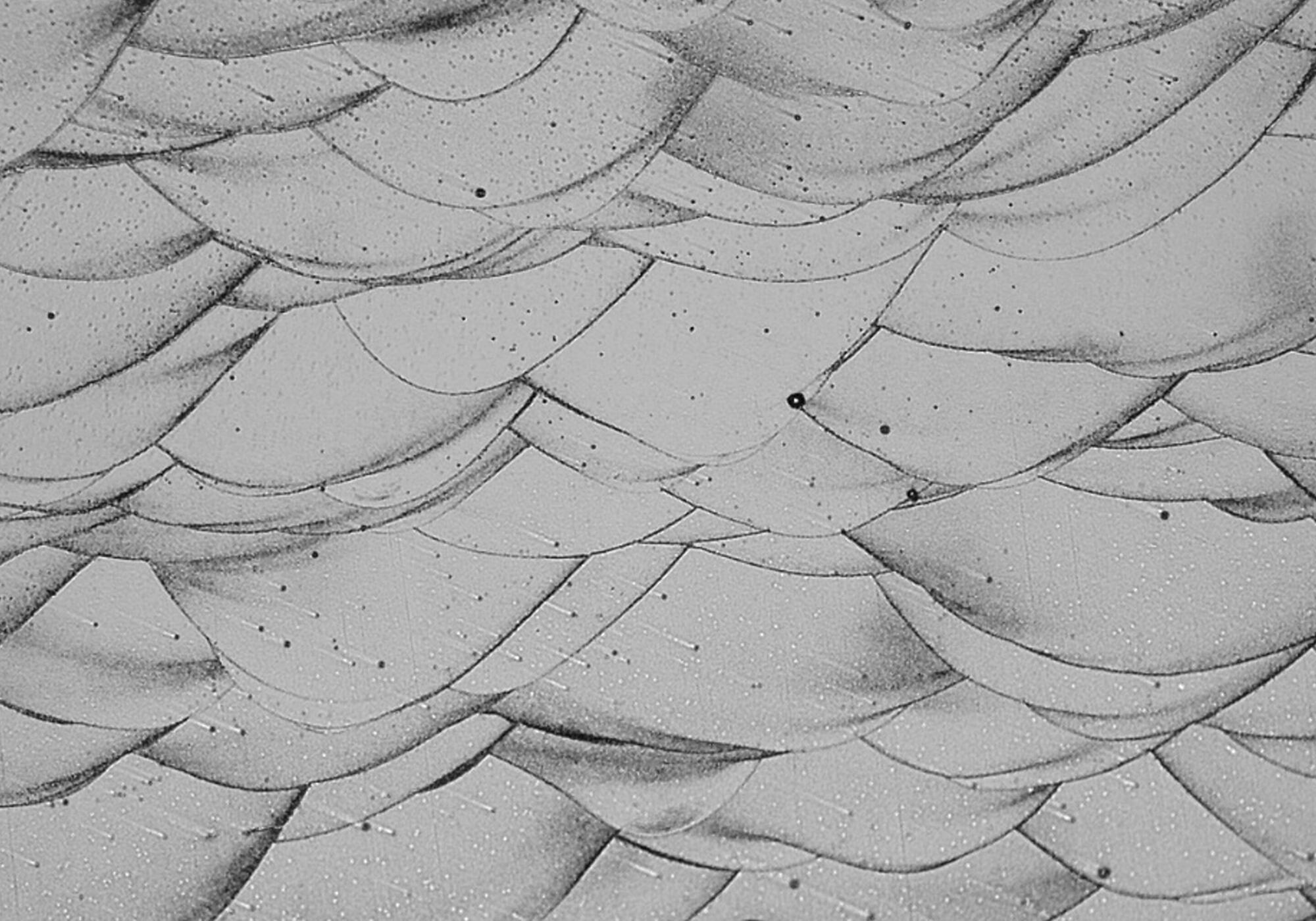

In a low-pressure vacuum chamber, water evaporates rapidly at room temperature. As each water molecule evaporates, it takes with it a small amount of heat, causing the remaining water to become increasingly colder, eventually cooling to below 0°C. At that point, the water is still liquid, but supercooled. As soon as the ultra-thin stream (about as thin as a human hair: 16 micrometers) hits the already formed layer of ice, it freezes instantly.

Aluminum is prized for being lightweight and strong, but at high temperatures it loses strength. This has limited its use in engines, turbines, and other applications where parts must stay strong under high temperature conditions. Researchers at Nagoya University have developed a method that uses metal 3D printing to create a new aluminum alloy series optimized for high strength and heat resistance. All new alloys use low-cost, abundant elements, and are recycling-friendly, with one variant staying both strong and flexible at 300° C.

The study is published in Nature Communications.

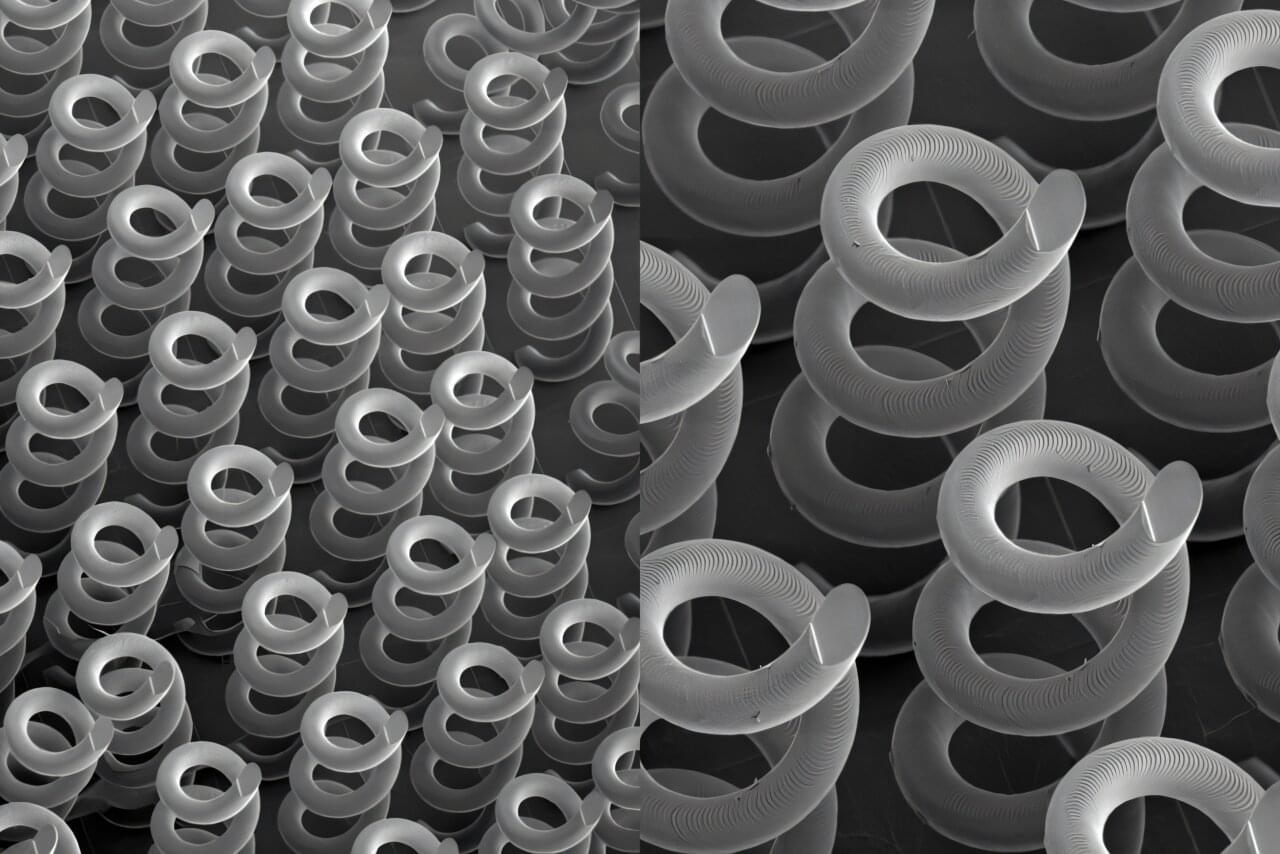

Researchers at Lawrence Livermore National Laboratory (LLNL) have optimized and 3D-printed helix structures as optical materials for terahertz (THz) frequencies, a potential way to address a technology gap for next-generation telecommunications, non-destructive evaluation, chemical/biological sensing and more.

The printed microscale helices reliably create circularly polarized beams in the THz range and, when arranged in patterned arrays, can function as a new type of Quick Response (QR) for advanced encryption/decryption. Their results, published in Advanced Science, represent the first full parametric analysis of helical structures for THz frequencies and show the potential of 3D printing for fabricating THz devices.