Thanks to 3D printing, scientists can now recreate any organ in the human body.

Early probes are one thing, but can we build a continuing presence among the stars, human or robotic? An evolutionary treatment of starflight sees it growing from a steadily expanding presence right here in our Solar System, the kind of infrastructure Alex Tolley examines in the essay below. How we get to a system-wide infrastructure is the challenge, one analyzed by a paper that sees artificial intelligence and 3D printing as key drivers leading to a rapidly expanding space economy. The subject is a natural for Tolley, who is co-author (with Brian McConnell) of A Design for a Reusable Water-Based Spacecraft Known as the Spacecoach (Springer, 2016). An ingenious solution to cheap transportation among the planets, the Spacecoach could readily be part of the equation as we bring assets available off-planet into our economy and deploy them for even deeper explorations. Alex is a lecturer in biology at the University of California, and has been a Centauri Dreams regular for as long as I can remember, one whose insights are often a touchstone for my own thinking.

By Alex Tolley

It looks like Self Driving cars may create a US organ shortage that finally acts as the Kick in the Ass to force stem cell generated organs on to the market. Enough of the ‘in the future’ we might have these Nonsesne.

Science, however, can offer better a better solution.

The waiting lists for donor organs are long — 120,000 people on a given day — and ever increasing. With fewer donor organs to go around, researchers are working on other ways to get people the parts they need. With help from 3D printing and other bioengineering technologies, we will eventually be able to grow our own organs and stop relying on donors.

Related: How Technology is Tackling Joe Biden’s Cancer Moonshot

“It’s like a race in which there’s multiple different players, but no matter which one of them winds up winning, it’s good,” says Ali Khademhosseini, a bioengineer at Harvard Medical School.

Glad Intel is moving this dial on their side as I have said for over a year they must do this to remain relevant. I would also encourage them to enter into a large 3D/4D printer partnership to develop a high speed printer that can print diamoide particles as they will need this bi-product to ensure stability in their chips and any other QC data storage and transfer processing. I do say they will need a group focused on Quantum Bio R&D as we begin to progress more of a integrated tech-bio system approach.

Intel realizes there will be a post-Moore’s Law era and is already investing in technologies to drive computing beyond today’s PCs and servers.

The chipmaker is “investing heavily” in quantum and neuromorphic computing, said Brian Krzanich, CEO of Intel, during a question-and-answer session at the company’s investor day on Thursday.

“We are investing in those edge type things that are way out there,” Krzanich said.

Add RadioBio/ Quantum Biosystem technology and this will be perfect.

Soft robotics researchers at the University of Wollogong (UOW) in Australia have used 3D printing to build a realistic robotic hand that can be controlled by brain signals and which has a surface texture similar to human skin.

Dr Rahim Mutlu (left), Professor Gursel Alici, and their 3D printed hand collection

3D printed bridge in Spain. Could this some day be our answer to reducing costs around US state and county infrastructure costs related to bridges and other structural repairs related to infrastructure?

The pedestrian crossing 3D-printed bridge installed in the urban park of Castilla La Mancha in Madrid, Spain, back in December is now ready to be used.

The 39-foot-long bridge was printed in micro-reinforced concrete at the Institute for Advanced Architecture of Catalonia.

In addition to the 3D printing, the production process was also environmentally friendly allowing the team to optimize the distribution of materials, minimize the amount of water, and recycle the raw material during manufacture.

Nice.

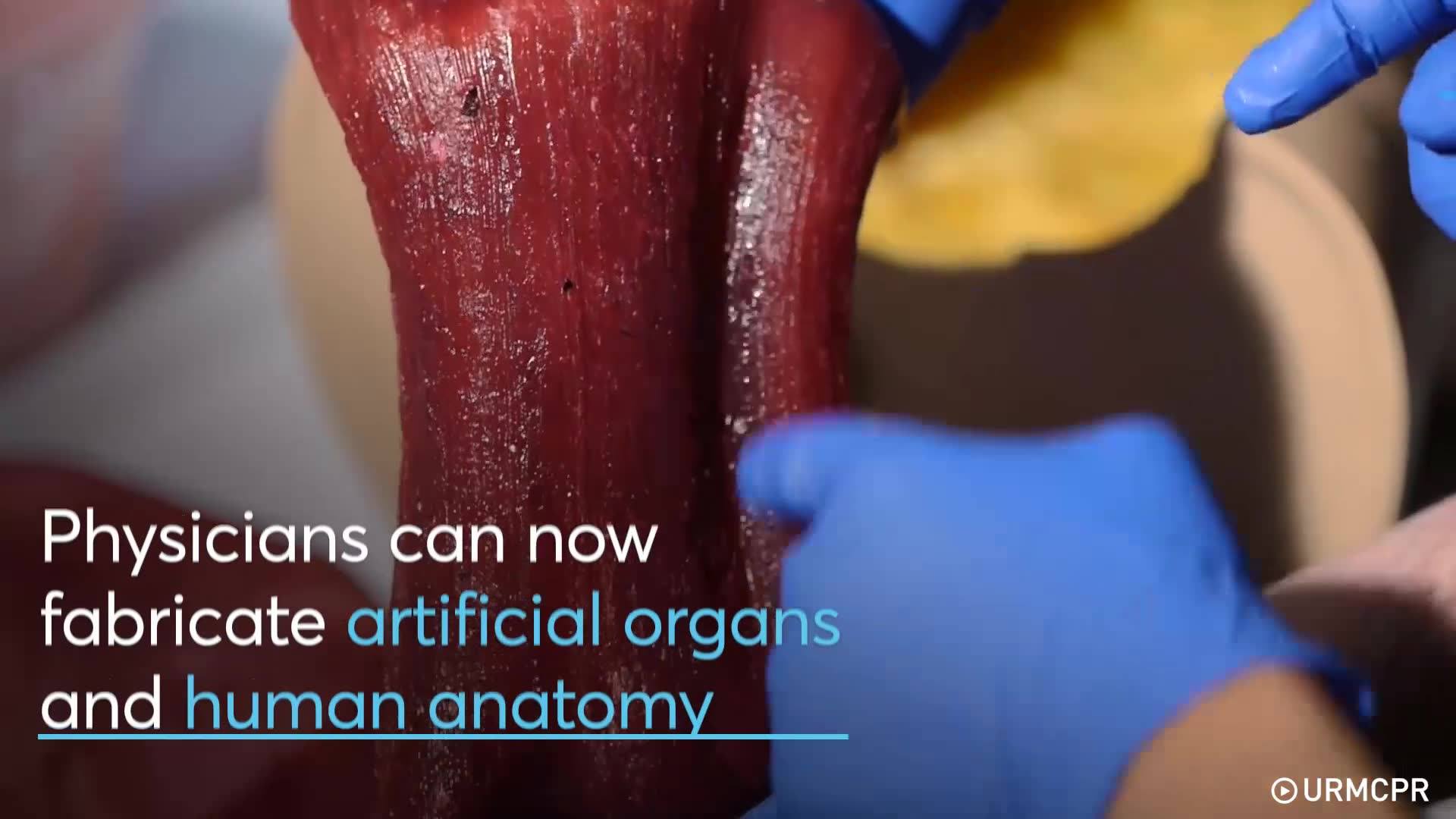

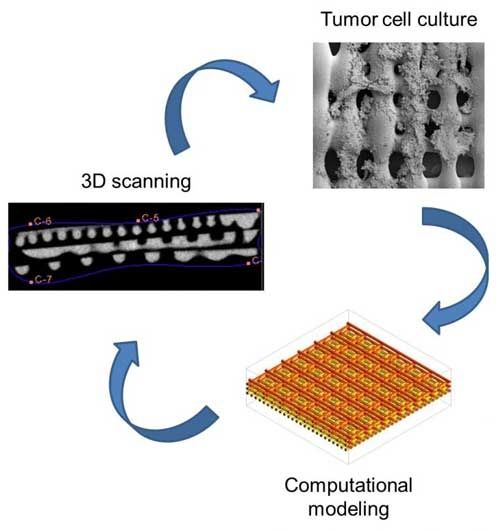

Testing treatments for bone cancer tumors may get easier with new enhancements to sophisticated support structures that mimic their biological environment, according to Rice University scientists.

A team led by Rice bioengineer Antonios Mikos has enhanced its three-dimensional printed scaffold to see how Ewing’s sarcoma (bone cancer) cells respond to stimuli, especially shear stress, the force experienced by tumors as viscous fluid such as blood flows through bone. The researchers determined the structure of a scaffold, natural or not, has a very real effect on how cells express signaling proteins that help cancer grow.

Sarcoma (bone cancer) cells proliferate on the surface of a 3D printed scaffold created at Rice University. Experiments at Rice showed that the size of pores in the scaffold, which mimics the extracellular matrix in bone, and the pores’ orientation make a difference in how cells proliferate in the presence of a flowing fluid, like blood. (Image: Mikos Research Group/Rice University)

We can now 3D print functional human skin.