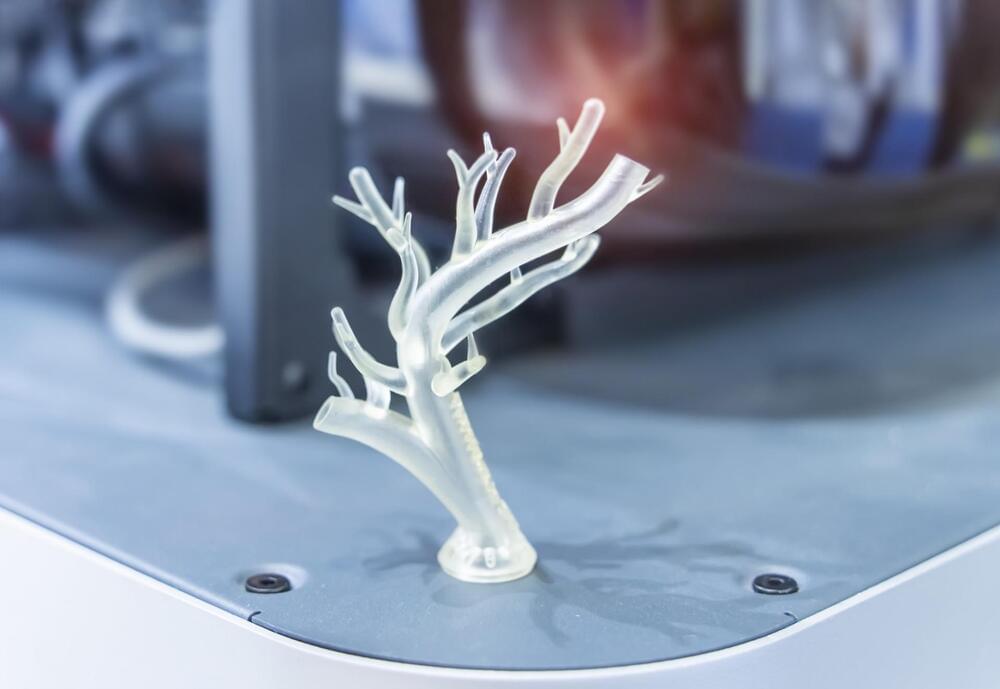

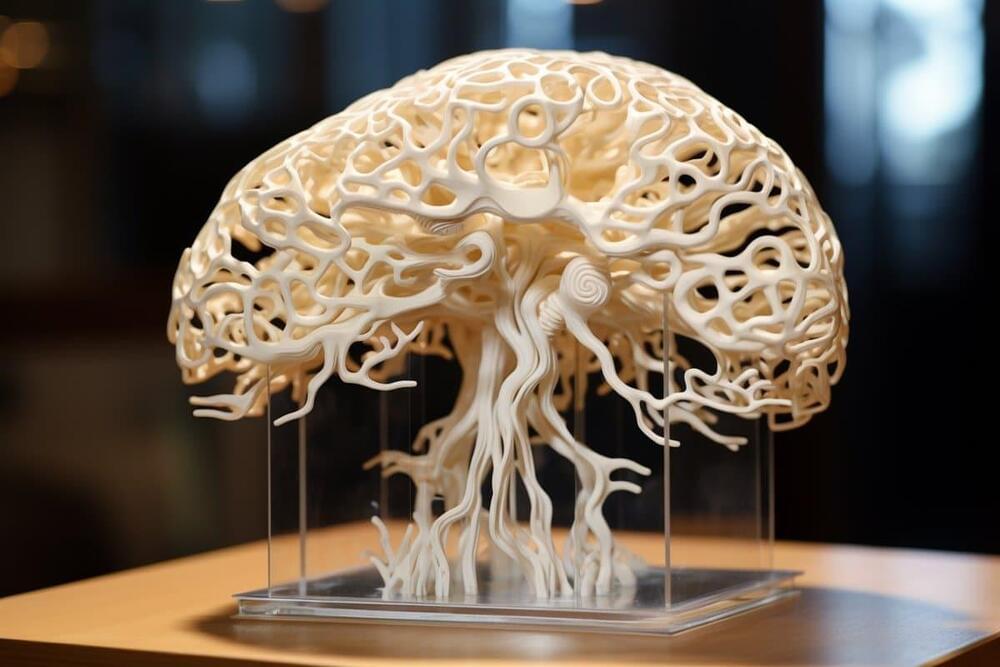

Scientists from medical tech company Fluicell have partnered with clinical R&D firm Cellectricon and the Swedish Karolinska Institutet university to 3D bioprint neural cells into complex patterns.

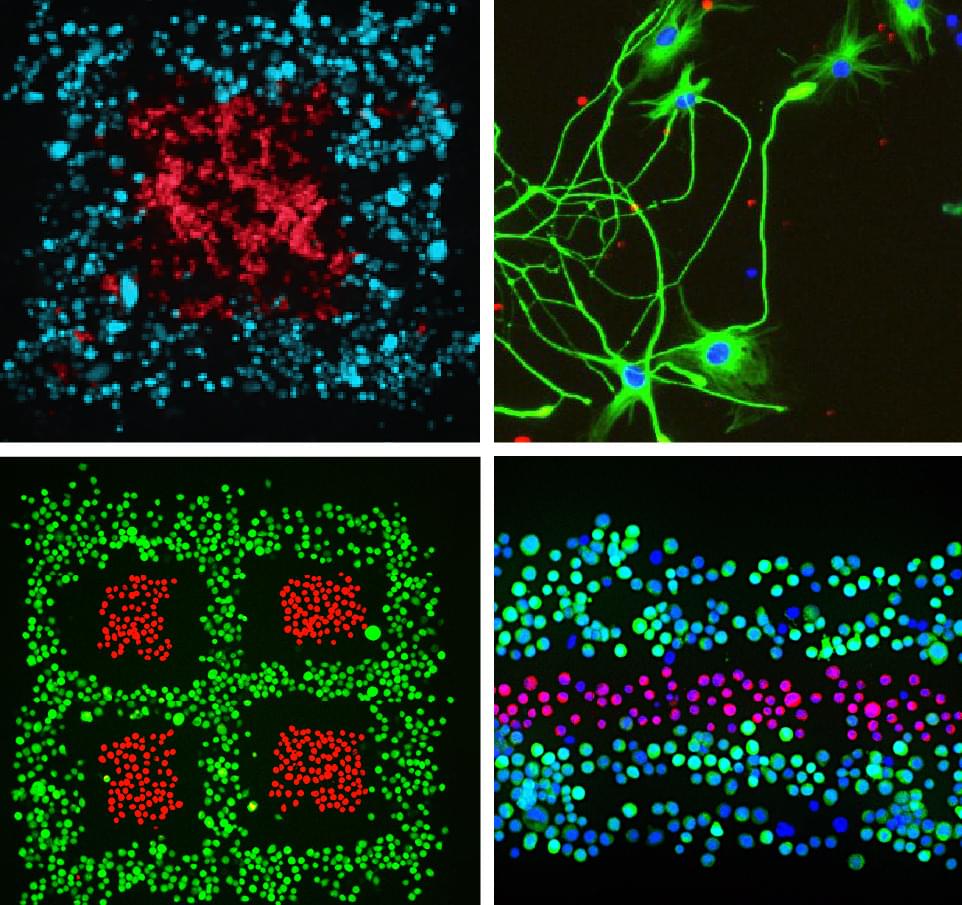

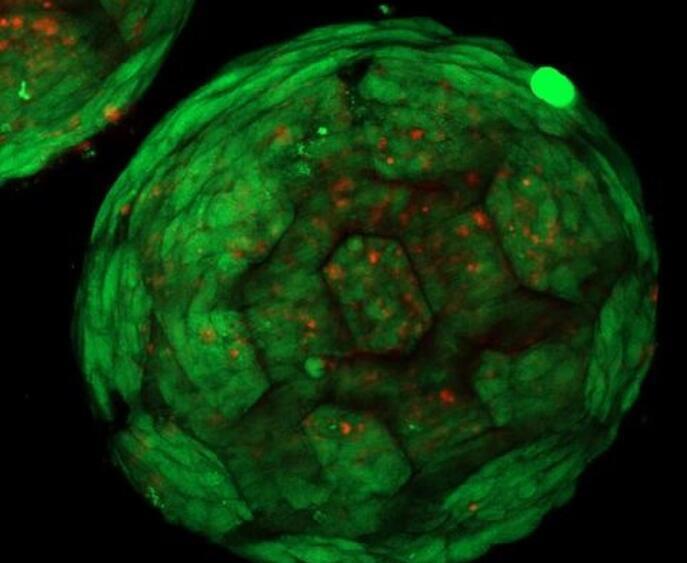

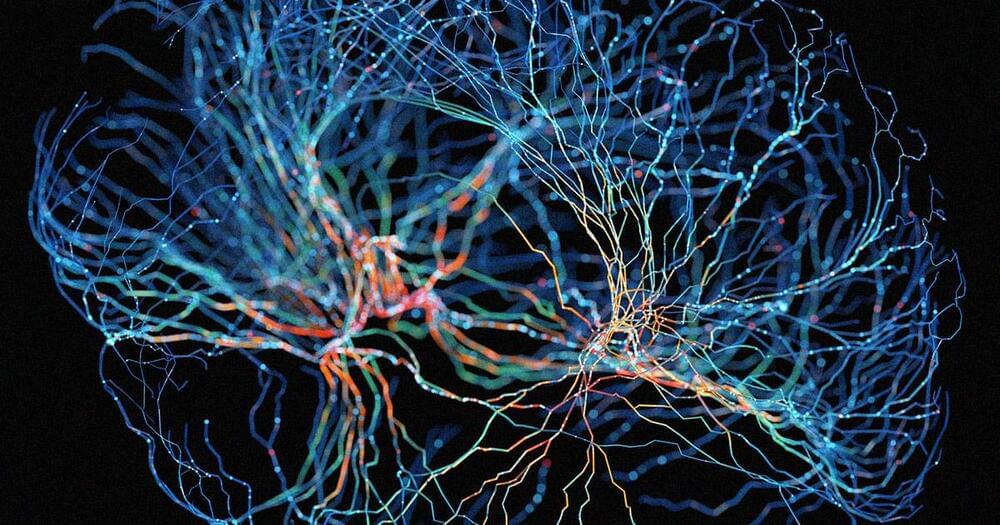

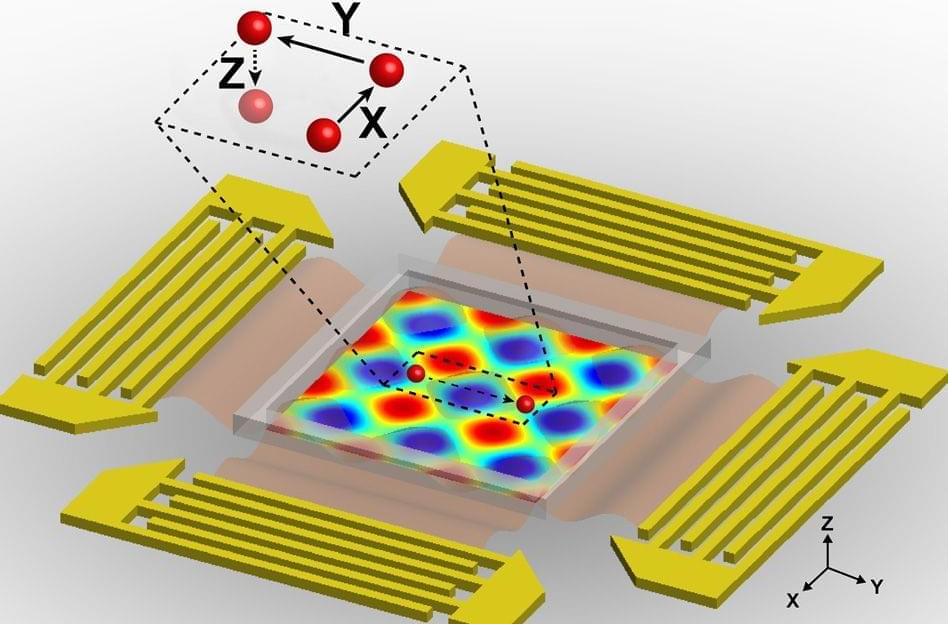

Using the microfluidic printheads featured on Fluicell’s Biopixlar platform, the researchers were able to accurately arrange rat brain cells within 3D structures, without damaging their viability. The resulting cerebral tissues could be used to model the progress of neurological diseases, or to test the efficacy of related drugs.

“We’ve been using Biopixlar to develop protocols for the printing of different neuronal cells types, and we are very pleased with its performance,” said Mattias Karlsson, CEO of Cellectricon. “This exciting technology has the potential to open completely new avenues for in-vitro modeling of a wide range of central and PNS-related diseases.”