Can they print one for me next?

Category: 3D printing – Page 58

Printer lickin‘ good: KFC is bioprinting chicken nuggets

“The partners are working together to develop the world’s first laboratory-produced chicken nuggets. The 3D printed nuggets are expected to be similar in taste and appearance to KFC’s original product, but will have the benefit of being more environmentally friendly to produce.”

When I think of KFC and its largely unchanging menu of fried chicken, I do not immediately think of innovation. However a new collaboration forged between the fast-food company and Russia-based bioprinting firm 3D Bioprinting Solutions might just change my mind. The partners are working together to develop the world’s first laboratory-produced chicken nuggets. The 3D printed nuggets are expected to be similar in taste and appearance to KFC’s original product, but will have the benefit of being more environmentally friendly to produce.

The bioprinted chicken nugget project is already underway, and the unlikely partners plan to have a final product ready for testing by this fall. The effort is part of KFC’s mission to create a “restaurant of the future” which leverages state-of-the-art technologies like 3D bioprinting to overcome solutions in the food industry today: such as finding more eco-friendly alternatives to traditional meat.

“At KFC, we are closely monitoring all of the latest trends and innovations and doing our best to keep up with the times by introducing advanced technologies to our restaurant networks,” said Raisa Polyakova, General Manager of KFC Russia & CIS. “Crafted meat products are the next step in the development of our “restaurant of the future” concept. Our experiment in testing 3D bioprinting technology to create chicken products can also help address several looming global problems. We are glad to contribute to its development and are working to make it available to thousands of people in Russia and, if possible, around the world.”

How 3D Printers Could Build Futuristic Moon Colony

Circa 2019

The European Space Agency (ESA) study is investigating how practical constructing a manned base on the moon only using 3D printing technology could be, given that it would rely primarily on lunar dirt for building materials.

“Terrestrial 3D printing technology has produced entire structures,” Laurent Pambaguian, who heads the project for ESA, said in a statement. “Our industrial team investigated if it could similarly be employed to build a lunar habitat.”

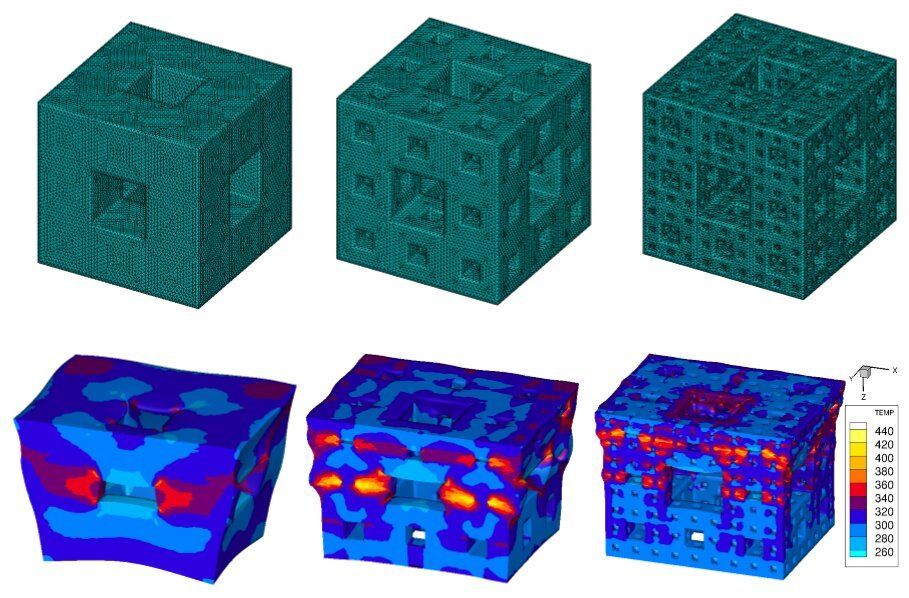

Shock-dissipating fractal cubes could forge high-tech armor

Tiny, 3D printed cubes of plastic, with intricate fractal voids built into them, have proven to be effective at dissipating shockwaves, potentially leading to new types of lightweight armor and structural materials effective against explosions and impacts.

“The goal of the work is to manipulate the wave interactions resulting from a shockwave,” said Dana Dattelbaum, a scientist at Los Alamos National Laboratory and lead author on a paper to appear in the journal AIP Advances. “The guiding principles for how to do so have not been well defined, certainly less so compared to mechanical deformation of additively manufactured materials. We’re defining those principles, due to advanced, mesoscale manufacturing and design.”

Shockwave dispersing materials that take advantage of voids have been developed in the past, but they typically involved random distributions discovered through trial and error. Others have used layers to reverberate shock and release waves. Precisely controlling the location of holes in a material allows the researchers to design, model and test structures that perform as designed, in a reproducible way.

3D Printing is Revolutionizing the Chocolate Industry

Charles Goulding and Ryan Donley of R&D Tax Savers discuss 3D printing as it impacts chocolateering.

Chocolate has been around for millennia now, dating as far back as early 1750 B.C., presumably in the area of the Gulf Coast of Vera Cruz where cocoa beverages or chocolate drinks were used in ceremonies by pre-Olmec peoples. Evidence suggests cacao pods may have even been used in alcoholic beverages as early as 1400 B.C. Today, the cacao bean has evolved to encompass a $50 billion chocolate industry worldwide that consists of edible chocolate confections being brought to mass markets.

3D rocket printer Relativity signs deal with Iridium and plans to build a California launchpad

Relativity Space, a growing startup that aims to almost entirely 3D-print rockets, on Wednesday announced it struck another major launch deal, as well as an agreement with the U.S. Air Force, to build a launchpad on the California coastline.

The Los Angeles-based rocket builder signed an agreement with satellite operator Iridium Communications, to launch up to six satellites as needed as early as 2023. Over the course of more than half a dozen launches with SpaceX, Iridium completed its second-generation satellite constellation in January 2019, with 66 operational satellites and 9 spares in orbit.

The Iridium deal means Relativity now has agreements to launch for five different companies, having previously announced contracts with Canadian satellite communications operator Telesat, California-based Momentus, Thai satellite broadband company mu Space and Seattle-based Spaceflight Inc. All the contracts have remarkably come before Relativity’s first launch, which is scheduled to happen before the end of 2021.

Researchers mimic nature for fast, colorful 3D printing

Brilliantly colored chameleons, butterflies, opals—and now some 3D-printed materials—reflect color by using nanoscale structures called photonic crystals.

A new study that demonstrates how a modified 3D-printing process provides a versatile approach to producing multiple colors from a single ink is published in the journal Science Advances.

Some of the most vibrant colors in nature come from a nanoscale phenomenon called structural coloration. When light rays reflect off these periodically placed structures located in the wings and skins of some animals and within some minerals, they constructively interfere with each other to amplify certain wavelengths and suppress others. When the structures are well ordered and small enough—about a thousand times smaller than a human hair, the researchers said—the rays produce a vivid burst of color.

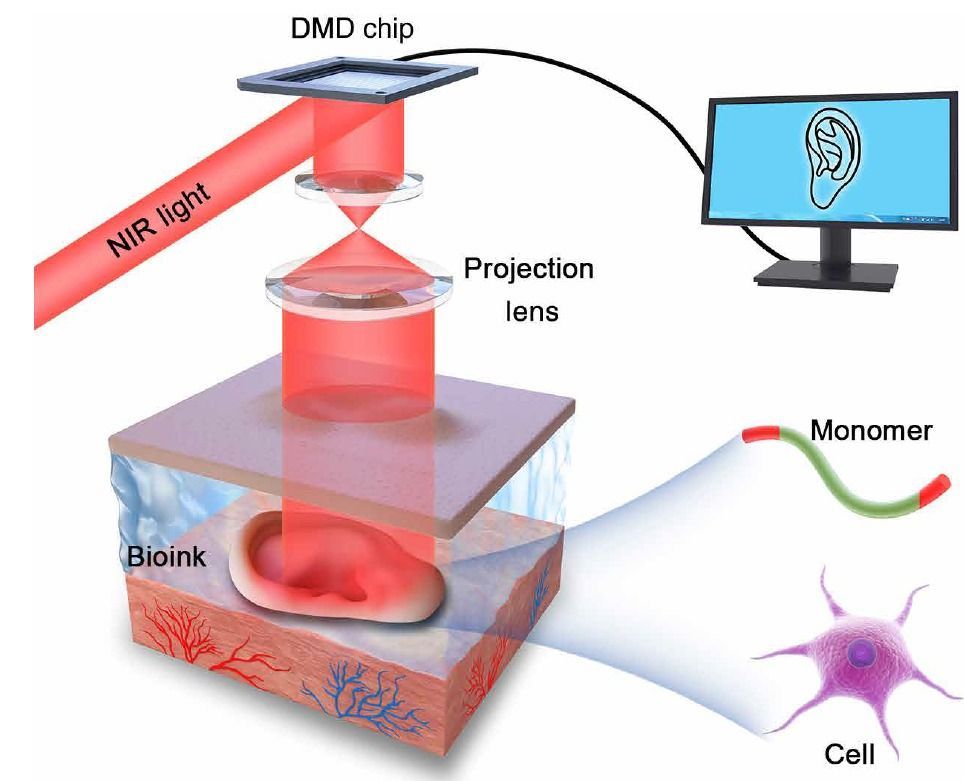

Video: Scientists grow a human ear with new, skin-crawling 3D printing method

Their new approach to 3D bioprinting and allows for non-invasive tissue growth and wound healing. It works through injecting bioink cells, the additive material traditionally used in 3D bioprinting, under the skin and using near-infrared light to penetrate the tissue and transfer customizable building designs — like an ear or an abstract shape — to newly injected cells.

The ear began to form in just 20 seconds.

Using a new approach to 3D bioprinting researchers have designed a way to non-invasively grow a wide range of customizable tissue under living skin.