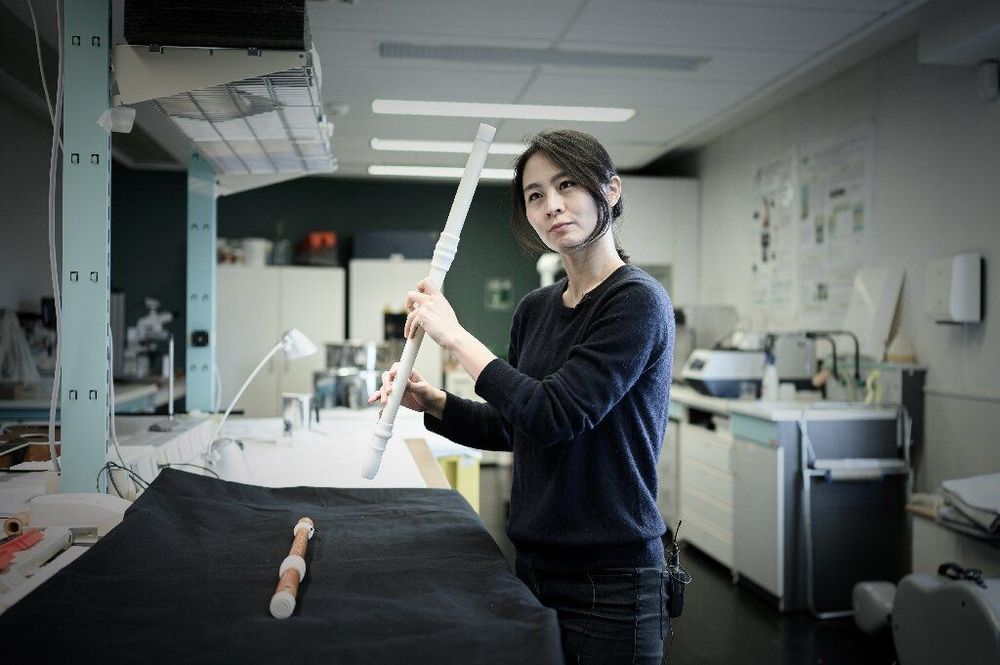

This handheld 3D printer deposits layers of skin tissue, and could one day help to heal deep wounds. Instead of waiting for skin patches to grow in a Petri dish, you apply it directly.

A team of Canadian scientists has successfully applied skin tissue to burn wounds using a handheld 3D printer. This technology may become a game-changer in the way severe burn victims are treated.

The handheld skin 3D printer, the work of scientists at the University of Toronto Engineering and Sunnybrook Hospital, was first shown back in 2018. Since then it has undergone a major redesign that improves upon the initial model’s functionality.