An advanced bionic arm can be life-changing for a person with an upper limb amputation. But in India, with a population of nearly 1.4 billion and average income of just $2,000 a year, advanced prosthetics are financially out of reach for many amputees.

So the Indian startup Makers Hive developed one that’s not only 90% cheaper, but also more functional.

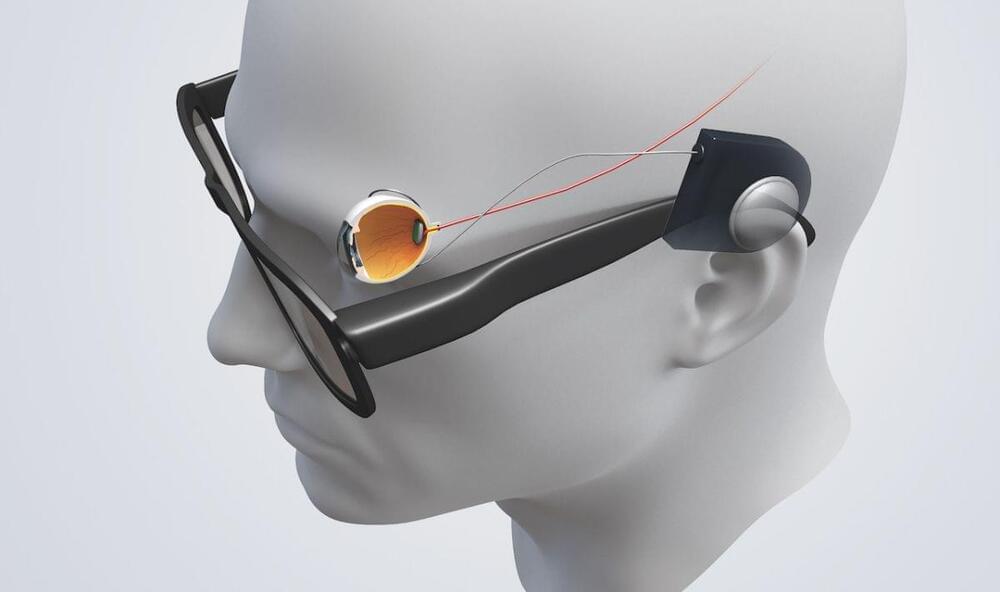

Advanced prosthetics: A bionic arm contains sensors that press against the skin of the wearer’s residual limb to detect electrical signals from their nerves.

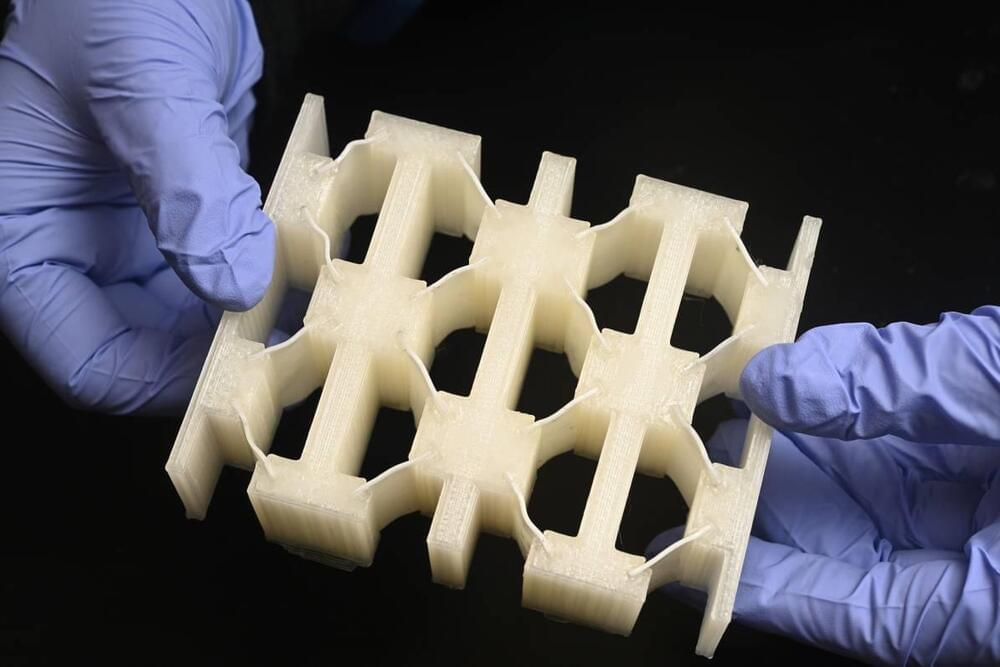

The 3D-printed, lightweight KalArm is the result of those efforts. It features 16 grips, customizable panels, and a companion app, which can be used to monitor the arm’s performance, as well as install firmware updates.

Indian startup Makers Hive has developed a bionic arm that’s not only 90% cheaper than most, but also more functional.