The battery wars are heating up as the modern global economy begins transitioning to a low-carbon future.

The Hydromea Exray wireless drone is an underwater drone that uses optics instead of cables for many effortless applications.

Donate to Paypal…[email protected].

https://www.facebook.com/BeholdFuture.

Automating remote, inspection and monitoring of submerged assets.

CUT THE CORD

At Hydromea, they believe that the restrictive underwater robotics space requires a paradigm shift to help the rapidly growing Ocean Economy become greener, more sustainable agent on our planet and at a price point that is affordable and scalable.

Hydromea are convinced that investing in hardware and software technologies that allow us to CUT THE CORD is the necessary and much awaited step towards this direction. With that, we disrupt the underwater inspection and monitoring market, making it significantly more efficient and affordable, enabling unprecedented access to submerged assets, never available before. Join us and be a part of the underwater robotics revolution!

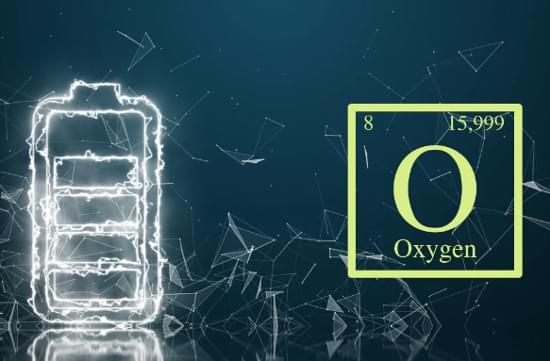

A transition to a carbon-free economy is the reality of the modern energy industry. Reduction in CO2 emission is one of the main challenge in energy engineering in the last decades. Renewable energy sources are playing an important role on the way to a zero-carbon economy [1,2]. Solar energy is one of the main and almost unlimited energy sources in the World. The different technologies of solar energy use have been developed in the last years [[3], [4], [5], [6], [7], [8]]. However, even though the progress in the development of solar energy technologies is notable, there are a lot of challenges for energy science. One of them is the fact that more than 60% of electricity is produced by conventional technologies via hydrocarbon fuel combustion: steam turbines, gas turbines, etc. While the share of electricity produced by using solar energy is no more than a few percent [9].

Among various ways of utilization of solar energy for electricity generation, a combination of solar energy with the traditional steam and gas turbine cycles can be highlighted. The power plants where solar energy is combined with conventional power cycles are named integrated solar combined cycle systems (ISCCS). In these systems, solar energy is used to produce heat and after that heat is used to generate mechanical work or electricity.

Combined cycle power plants (CCPP) show one of the highest energy efficiency among conventional power plants [10]. The modern cycles with high-temperature gas turbines have an efficiency up to 70% and even higher. In such cycles, the high-temperature gas turbines with the turbine inlet temperature (TIT) up to 1,600 °C are applied [11,12]. In the last years, a lot of various integrated solar combined cycle systems (ISCCS) were developed by various scientists and engineers. The main way to use solar energy in such cycles is a steam generation in CCPP [[13], [14], [15], [16]]. In other words, solar energy in such ISCCS is utilized as an energy source in a steam turbine cycle.

As per the company, traditional rovers may not be able to traverse everywhere and perform tasks like their drone-like hopper.

For decades, Earth’s natural satellite has been one of the most popular destinations for space exploration. The upcoming Artemis missions, along with the excitement on establishing a human settlement on the Moon, have collectively boosted the lunar economy market substantially in recent years.

Several startups have been preparing to offer their technological solutions to gain a better understanding of the valuable resources available and provide services to future astronauts.

The researchers suggest that a pervasive design perspective is driving the development of AI with increasingly human-like features. While this may be appealing in some contexts, it can also be problematic, particularly when it is unclear who you are communicating with. Ivarsson questions whether AI should have such human-like voices, as they create a sense of intimacy and lead people to form impressions based on the voice alone.

In the case of the would-be fraudster calling the “older man,” the scam is only exposed after a long time, which Lindwall and Ivarsson attribute to the believability of the human voice and the assumption that the confused behavior is due to age. Once an AI has a voice, we infer attributes such as gender, age, and socio-economic background, making it harder to identify that we are interacting with a computer.

The researchers propose creating AI with well-functioning and eloquent voices that are still clearly synthetic, increasing transparency.

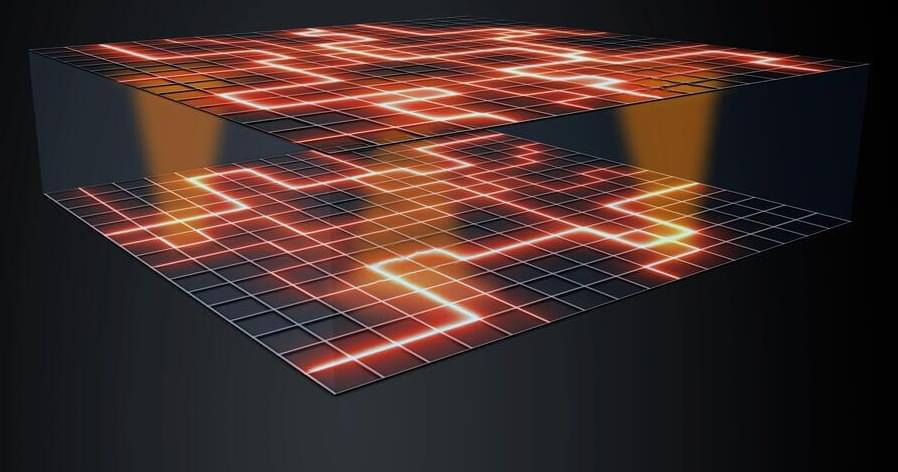

In 2010 Prof. Shlomo Havlin and collaborators published an article in the journal Nature proposing that the abrupt electricity failure causing the famous 2003 Italy blackout was a consequence of the inter-dependency of two networks. According to Havlin’s theory the dependency between the power network and its communication system led to cascading failures and abrupt collapse. Havlin’s seminal work ignited a new field in statistical physics known as “network of networks” or “interdependent networks” and paved the way for understanding and predicting the effects of the interaction between networks.

The main novelty of Havlin’s model is the existence of two types of links that represent two qualitatively different kinds of interactions. Within networks, links between nodes describe connectivity such as electric power or communication connections. Between networks, on the other hand, links describe dependency relationships in which the functionality of a node in one network depends on the functionality of a node in the other. The communication hubs need electricity and the electric power stations depend on communication control. This dependency leads to a cascading effect in which failure of a single node in one of the networks could lead to an abrupt breakdown of both networks.

Over the past decade or so since, Havlin, from the Department of Physics at Bar-Ilan University in Israel, and others have applied this concept to a variety of abstract systems, such as the internet, road traffic, the economy, infrastructure, and more. But being a theorist, Havlin was unable to manifest the hypothesis on real experimental physical systems and thus the theory couldn’t be confirmed in controlled experiments, nor could it be implemented for device-type applications.

At its I/O developer conference, the search giant needs to rethink its AI strategy if it wants to catch Microsoft. The missing element? Experimentation.

Google has had a rough six months. Since ChatGPT launched last November — followed by the new Bing in February and GPT-4 in March — the company has failed to establish its AI credentials. Its own offering, the “experimental” chatbot Bard, compares poorly to rivals, and insider reports have portrayed a company in panic and disarray. Today, at its annual I/O conference, the company needs to convince the public (and shareholders) that it has a meaningful response. But to do that, it needs a new playbook.

AI outputs are increasingly defining the cultural moment — just not Google’s.

TerraPower, founded by billionaire and Microsoft co-founder Bill Gates in 2008, is opening a new nuclear power plant in Kemmerer, Wyoming. The plant will be the first of its kind, with the company hoping to revolutionize the nuclear energy industry in the U.S. to help fight climate change and support American energy independence.

“Nuclear energy, if we do it right, will help us solve our climate goals,” Gates told ABC News. “That is, get rid of the greenhouse gas emissions without making the electricity system far more expensive or less reliable.”

Gates met with ABC News’ chief business, economics, and technology correspondent Rebecca Jarvis in Kemmerer to talk about the project.

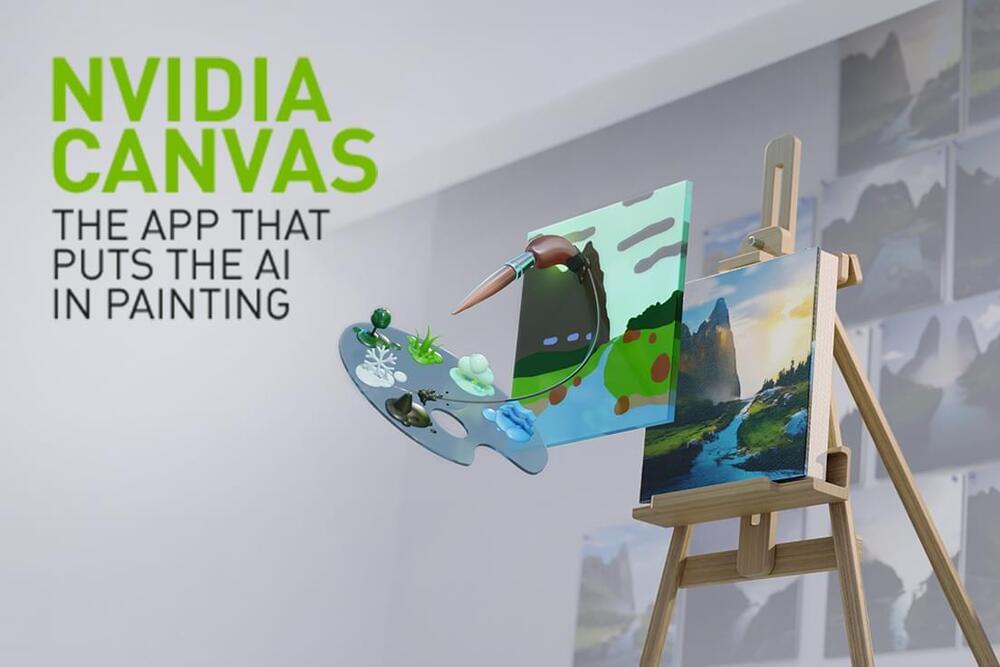

With all the controversy surrounding AI art, I’m surprised that NVIDIA is so rarely discussed. Unlike other AI art technologies, NVIDIA facilitates drawing landscapes in an interactive fashion. You sketch out rough blobs and then the AI converts your shapes into rocks, grasses, dirt, trees, and other selectable material types. I think that this kind of tool deserves much more attention since it empowers human artists to create with AI as a partner and gives us more creative control over the final result. Sure, NVIDIA itself is somewhat limited, but the principle of it is very compelling and I can easily envision people developing lots of improved versions that can draw more than just landscapes. I think it is surprising that this kind of approach has not caught on, but perhaps there are economic reasons that I’m not aware of which explain the relative lack of interactive AI art tools.

Use AI to Create Backgrounds Quickly, or Speed up your Concept Exploration.